If you are looking to produce large-head or small-head nails,simply provide us with your:

Wire diameter requirements

Nail length specifications

Monthly production volume (in tons)

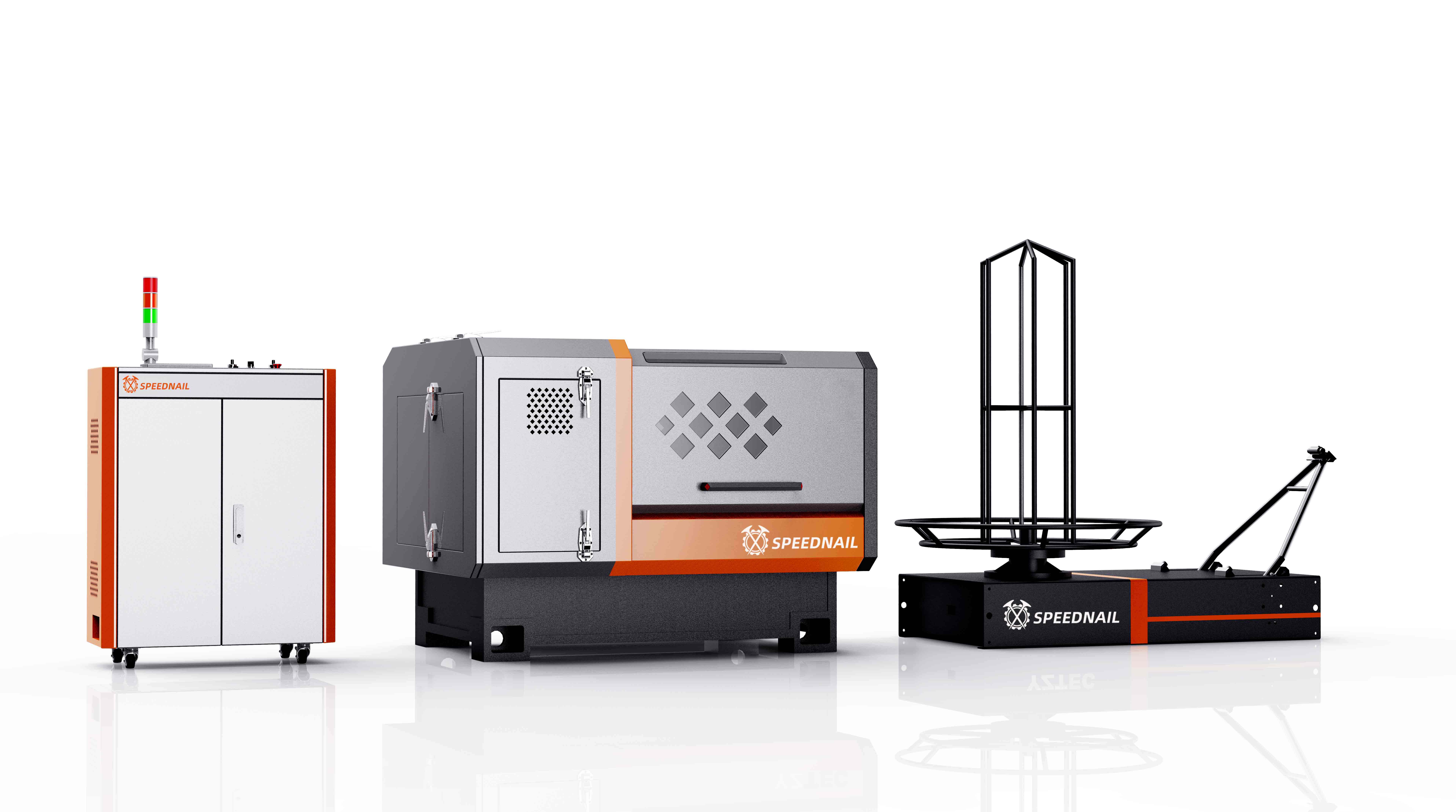

Our engineering team will design a complete, optimized production line solution tailored to your exact needs, which may include:

• Wire drawing machines

• High-speed nail making machines

• Thread rolling machines

• Nail collating systems

• Nail cleaning equipment

Why Choose Speednail?

Turnkey solutions from raw material to finished nails

Custom-configured production lines

Output-optimized machinery selection

Lifetime technical support

Contact our engineers today for your free line design consultation!